Shenzhen 3DOE Technology Co.,Ltd.

Application of 3D scanner in reverse modeling of impeller

3d scanner in the reverse design has an irreplaceable role, greatly saving manpower and material resources.

Reverse engineering strictly follow the "Spot - Line - Area" process, this process is a positive analog design, through point cloud object, speculation original designer design intent to accurately reconstruct the model feature. Simply, reverse engineering is the process designers to model reconstruction, which is re-learning process, and be able to innovate on this basis.

1. 3d Scanning the workpiece

General product slightly surface treatment (see below)

A spray imaging agent

B posted marker

C multi-angle scanning

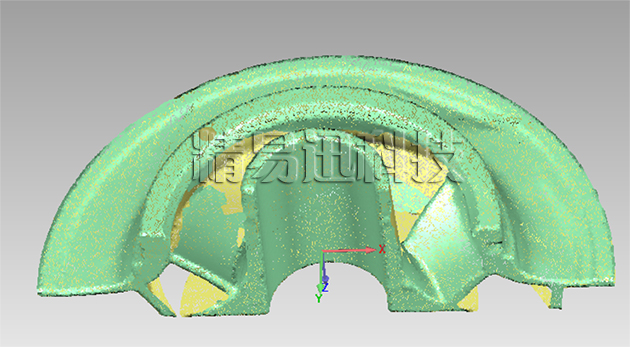

2.After scanning, to give the object surface point cloud data

3.Using software such as Geomagic surface to process point cloud data, noise removal, packaging fill the hole, put the processing and other functions, form a triangular mesh data (Can be directly used for 3D printing)

If the customer needs to develop a product or a model, we need to generate the geometric model surfaces, which we need to do a reverse modeling (reverse common software UG / PROE / CATAI Solidworks, etc.)

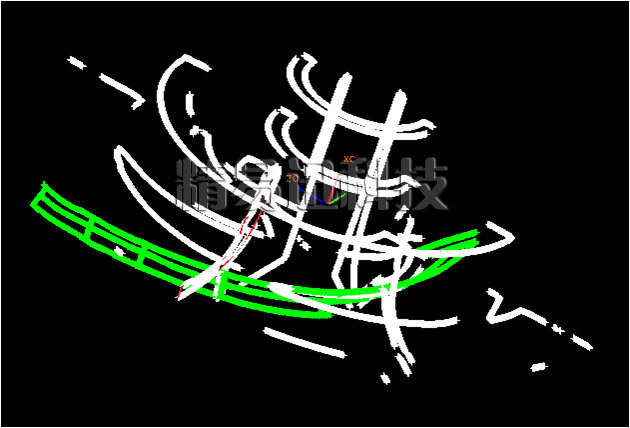

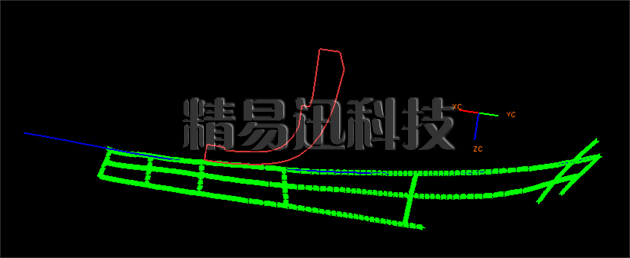

<1>Combined with scanning point cloud extracting feature points

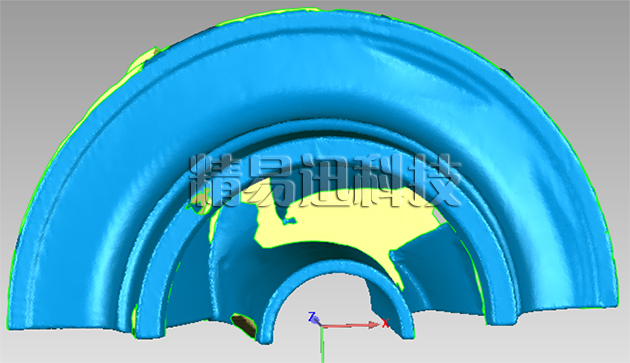

<2>Importing three-dimensional software, describing the spline based on the extracted feature points

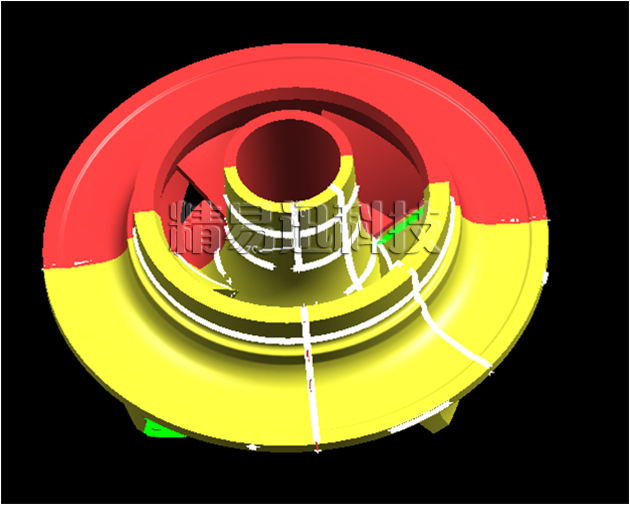

<3>After the rotation, to give the entity

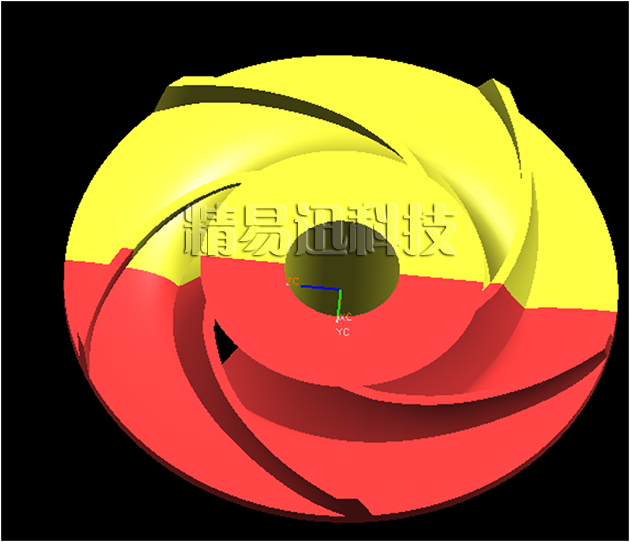

<4>Removing scanning feature point, a complete geometry came out places. Then we can go to the sub-processing

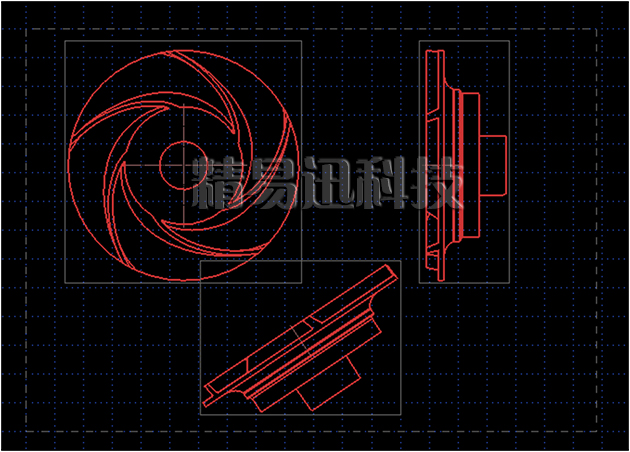

<5>Generate CAD drawings can be cutting, other operating CAM processing size measurements and so on .